Now it's time to caulk ("cork") those seams, some of them gaping rather widely.

The once shutter-tight fits have opened up as the green planks have dried out considerably.

Its what the Klondike stampeders had to deal with too, with their green planks...

|

Bruce and Millie developed a system of double-wound

cotton strands, built up like rope, to suit the gaping seams.

First, twist is applied to single

strands (using a hook chucked into the Makita), then the strand is

doubled and twisted the opposite direction. For most seams this provided

cotton of suitable bulk and was easier to deal with than looped tucks.

|

|

Cotton strands are first tucked at the stern, then set forward, with

caulking mallet and iron. The spiral of the double-wound strands is

clearly visible in the tails hanging off of the bottom seams.

|

(click to enlarge)

|

|

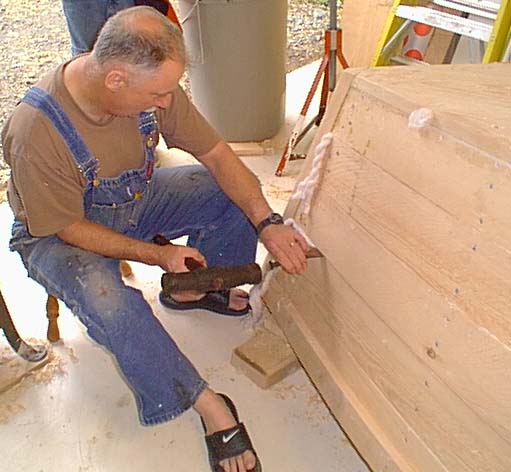

Closeup of Harry at work on his caulking stool,

with the old caulking mallet and irons. First tuck.

|

(Click to enlarge)

|